德国萨尔锻钢厂成功交货!先进汽轮机转子助力碳减排和气候改善

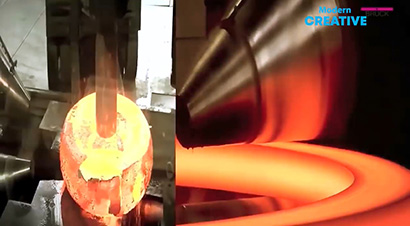

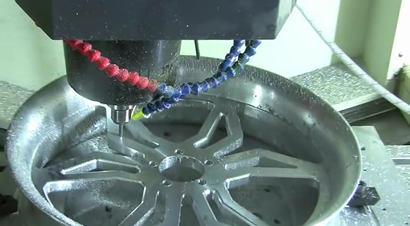

近日,德国萨尔锻钢厂(Saarschmiede) 成功制造42吨级含9%铬的先进汽轮机中压转子锻件,其原材料在能源发电设备行业也称FB2钢。

该型先进的中压转子打破了萨尔自身在FB2整锻转子领域的生产记录,是当今全球最新一代超超临界 (USC) 汽轮机组的核心部件。采用这种中压转子可以使USC汽轮机在蒸汽再热循环和更高的蒸汽温度下稳定运行,从而提高火电厂的发电效率,有效减少每千瓦时的煤炭消耗量以及碳排放量,与全球尽早实现碳中和的目标一致。

同时,该型中压转子的顺利交货也延续了Saarschmiede为客户提供各种尺寸和重量级别的优质高合金粗加工转子的成功案例。

新闻来源: Saarschmiede LinkedIn

英文原文 如下:

Advanced Steam Turbine rotors made by Saarschmiede to reduce carbon emissions for a better climate!

Saarschmiede has launched an advanced Steam Turbine IP Rotor (Intermediate Pressure) of 42 tons with 9% Chromium, which is also known as FB2 Steel for the Power Generation market.

This advanced IP rotor breaks the record of its field. It is the core component of the most modern ultra supercritical (USC) steam turbine. Such IP rotor enables the USC steam turbine to run on steam re-heating cycle and at higher steam temperature, which increase the efficiency of the power plant. As a result, both coal consumption as well as carbon emission per KWHr will be reduced, in line with the global targets towards carbon neutrality.

It also continues Saarschmiede‘s success story of providing higher alloyed premachined rotors of various sizes and weight categories.

近日,德国萨尔锻钢厂(Saarschmiede) 成功制造42吨级含9%铬的先进汽轮机中压转子锻件,其原材料在能源发电设备行业也称FB2钢。